Knex instructions are detailed manuals guiding users through constructing complex models using rods, connectors, wheels, and gears. They cover basic techniques, troubleshooting, and advanced building tips.

What Are Knex Instructions?

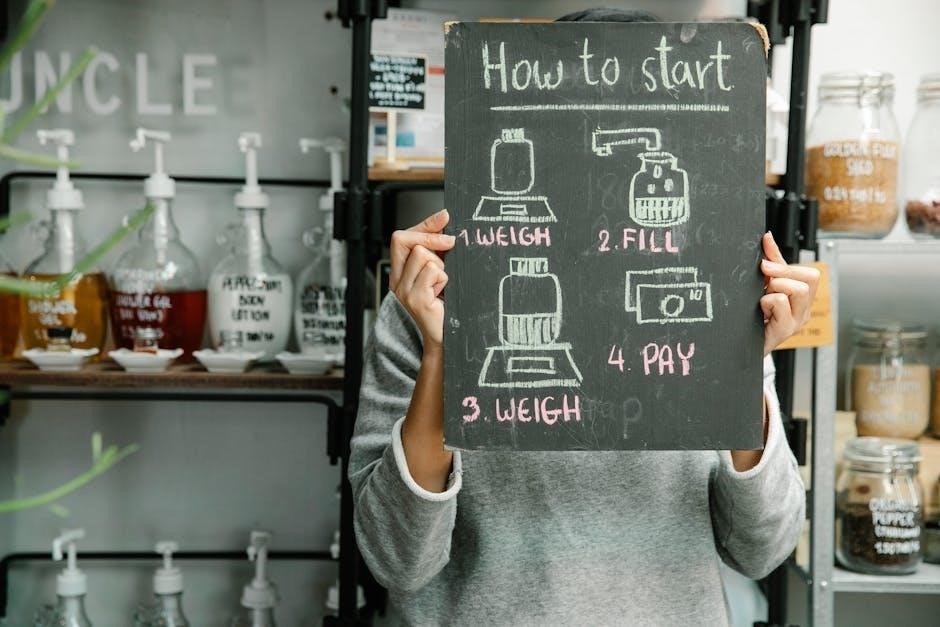

Knex instructions are detailed, step-by-step guides designed to help users assemble and create various structures using Knex sets. These manuals typically include visual diagrams and written descriptions to ensure clarity. They cover everything from basic models to complex machines, providing users with a clear roadmap to follow. Knex instructions often break down the building process into manageable steps, making it easier for both beginners and experienced builders to achieve their desired results. Additionally, these guides may include troubleshooting tips and advanced techniques for optimizing builds. The instructions are usually tailored to specific Knex sets, ensuring compatibility with the included parts. By following these guides, users can unlock the full creative potential of their Knex collection and bring their ideas to life with precision and confidence.

Essential Components of Knex Sets

Knex sets include rods, connectors, wheels, gears, and panels, which are fundamental for building structures. These parts work together to enable creativity and functionality in various models and designs.

Rods and Connectors

Rods and connectors are the backbone of Knex construction. Rods vary in length and serve as structural elements, while connectors link rods together, allowing for angles and joints. They ensure stability and flexibility, enabling users to create diverse models. Proper alignment and secure connections are crucial for durability. By mastering these components, builders can achieve intricate designs and sturdy structures.

Wheels and Gears

Wheels and gears are essential for creating motion in Knex models. Wheels enable rolling mechanisms, while gears facilitate mechanical movement and speed adjustments. They are often used in roller coasters, cars, and automated systems. Proper gear alignment and spacing ensure smooth operation. Combining wheels with gears allows for intricate animations and functional designs, enhancing the interactivity of Knex creations. These components are vital for building dynamic and engaging models.

Panels and Other Parts

Panels and other specialized parts add structural integrity and detail to Knex models. Panels, such as flat or angled ones, provide surfaces for attaching additional components. Clips, hooks, and spacers are versatile, enabling secure connections and precise alignment. These elements are crucial for stabilizing larger structures and preventing wobbling. Additionally, decorative parts like themed accessories enhance the visual appeal of models. Proper use of panels and accessories ensures durability and functionality, allowing builders to create intricate designs. These parts are essential for both beginner and advanced projects, offering endless possibilities for customization and creativity.

Basic Building Techniques

Mastering basic techniques, like sorting parts and following step-by-step guides, ensures a strong foundation. Aligning rods and connectors properly and using visual aids enhances accuracy and stability in builds.

Sorting and Organizing Parts

Sorting and organizing Knex parts is crucial for efficient building. Begin by categorizing rods, connectors, wheels, and gears into separate groups. Use a tray or container to keep small pieces from getting lost. Align parts according to their shape and size to match the instructions easily. For complex models, like the Knex Ball Machine or Mecha Strike Roller Coaster, organizing pieces by type ensures you can locate them quickly. Always refer to the visual guides in the manual to identify each component accurately. Sorting also helps prevent misalignments and instability in the final structure. Regularly reorganizing your parts as you progress can save time and reduce frustration. This step is especially vital for beginners to develop a systematic approach to building. By maintaining a tidy workspace, you can focus on creativity and precision, ensuring a successful and enjoyable Knex experience.

Following Step-by-Step Instructions

Following step-by-step instructions is essential for successfully building Knex models. Start by carefully reading each instruction to understand the sequence of actions. Align parts exactly as shown in the manual to ensure proper fit and functionality. Pay attention to visual guides, which often highlight specific connections or orientations. Double-check each step to avoid mistakes that may require disassembling later. For complex models, like the Knex Ball Machine or Mecha Strike Roller Coaster, breaking the instructions into smaller sections can make the process less overwhelming. Use a well-lit workspace to easily see small details. Patience and attention to detail are key to achieving a sturdy and accurate final structure. By adhering to the instructions, you can unlock the full potential of your Knex set and enjoy the satisfaction of creating intricate designs.

Using Visual Guides

Visual guides are a cornerstone of Knex instructions, providing clear, illustrated steps to help builders of all skill levels. These guides use detailed images to show how parts connect, making it easier to understand complex assemblies. Color-coded highlights often emphasize specific components or actions, reducing confusion. For intricate models, like the Knex Ball Machine or Mecha Strike Roller Coaster, visual guides break down each stage into manageable parts. They also help identify potential misalignments early, preventing structural instability. By referencing these visuals alongside written instructions, builders can ensure accuracy and avoid mistakes. Visual guides are particularly useful for those who prefer learning through images rather than text, making the building process more accessible and enjoyable. Regularly referring to these guides can significantly enhance the overall Knex building experience.

Troubleshooting Common Issues

Knex instructions often address frequent challenges, such as missing pieces, misalignments, and unstable structures, offering practical solutions to ensure successful model assembly and functionality.

Identifying Missing Pieces

Identifying missing pieces is crucial for successful Knex model assembly. Begin by carefully reviewing the instruction manual to familiarize yourself with all required components. Next, organize your parts by type, such as rods, connectors, wheels, and gears, to ensure nothing is overlooked. If a piece is missing, refer to the manual or online guides for substitution suggestions. Additionally, double-check your inventory by comparing it to the provided parts list. If a piece is still missing, consider reaching out to the manufacturer or exploring community forums for alternatives. Proper identification and management of components ensure your project progresses smoothly and efficiently.

Correcting Misalignments

Misalignments can hinder the stability and functionality of your Knex model. To address this, start by disassembling the affected section and carefully realigning the components according to the instructions. Use the visual guides to ensure proper orientation and connection points. If a piece is slightly crooked, gently adjust it without forcing, as this may cause damage. Regularly check your progress to catch misalignments early, preventing larger issues later. For complex models, consider using a building mat or grid to maintain alignment. If unsure, consult online forums or community guides for tips on correcting specific misalignments. Patience and attention to detail are key to achieving a sturdy and precise structure. By addressing misalignments promptly, you can ensure your Knex creation stands strong and functions as intended.

Dealing with Unstable Structures

Unstable structures can be frustrating, but addressing them requires patience and a systematic approach. First, identify where the instability originates by gently testing each section. Loose connections or misaligned parts are common culprits. Tighten any weak joints or realign components according to the instructions. For added stability, consider reinforcing key areas with extra rods or connectors. If the base is uneven, adjust it to create a solid foundation. Testing the structure incrementally can help pinpoint issues early. For larger models, incorporating panels or supports can significantly improve stability. If instability persists, refer to visual guides or online tutorials for additional reinforcement techniques. Remember, even small adjustments can make a big difference in ensuring your Knex creation remains sturdy and functional. Regularly reviewing your work helps maintain balance and structural integrity.

Advanced Building Techniques

Advanced Knex techniques involve precision, creativity, and mastery of specialized parts. They enable intricate designs, incorporating motors for automation and complex mechanisms for dynamic models, enhancing overall functionality and visual appeal.

Tips for Complex Models

When tackling intricate Knex designs, planning is key. Start by thoroughly reviewing instructions and organizing parts. Use visual guides to align components accurately. Break the model into smaller sections, ensuring stability at each stage. Experiment with different connector angles to achieve precise alignments. For multi-functional elements, test individual mechanisms before integrating them; Incorporate reinforcements like doubled rods or triangular supports to prevent structural weakness. Leverage advanced techniques such as offset connectors or gear systems for smoother motion. Don’t hesitate to disassemble and adjust earlier steps if misalignments occur. Patience and attention to detail are crucial for successfully building complex models. Practice and experience will enhance your problem-solving skills, leading to more sophisticated creations over time.

Incorporating Motors and Automation

Incorporating motors and automation into Knex models adds dynamic functionality, enabling movement and interaction. Start by identifying compatible motor types and ensuring they fit your design. Use gears and connectors to transmit power smoothly. Plan motor placement carefully to maintain balance and stability. Experiment with synchronization techniques for multi-motor systems. Consider using battery packs or external power sources for consistent operation. Test motorized components separately before integrating them into the full model. Pay attention to alignment and gear ratios to optimize performance. For advanced automation, explore programmable elements or timed mechanisms. Always follow safety guidelines when working with electrical components. Mastering these techniques can elevate your Knex creations from static structures to engaging, interactive machines.

Knex instructions provide a comprehensive guide for building intricate models, from simple structures to complex machines. By following step-by-step instructions, users can master basic techniques like sorting parts and aligning components. Troubleshooting common issues, such as missing pieces or misalignments, ensures a smooth building experience. Advanced techniques, including motor integration and automation, allow for dynamic and interactive creations. Whether constructing roller coasters or ball machines, Knex instructions empower users to bring their imaginations to life. With patience and practice, builders can overcome challenges and create stunning, functional models. The satisfaction of completing a project fosters creativity and problem-solving skills, making Knex a timeless hobby for learners of all ages.